+86 159 8850 8540

+86 159 8850 8540

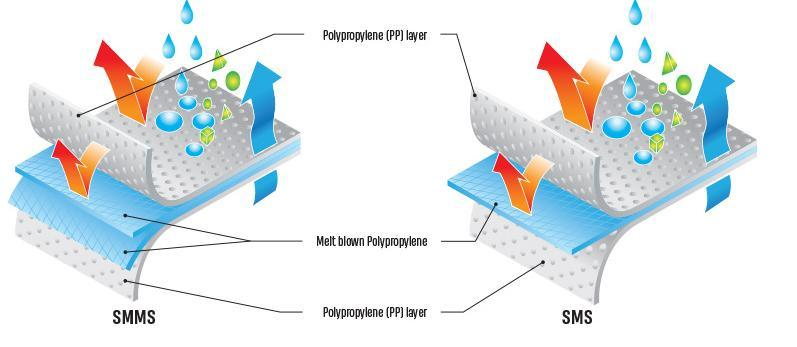

SMS &SMMS fabric is composed by nonwoven multi layer w spunbond and nonwoven PP that have a good performance widely use for isolation gown and other Medical healthcare products.

Color | White | Blue | Yellow | Custom Color |

Material | Spunbond Non-woven PP and Meltblown Multi Layers |

Weight(gsm) | 23 to 80gsm 40gsm SMMS meets Level 3 |

Width | Machine Width 3.2metre,production width per requestion for different final products |

Treatment | Anti Bacterials/Fluid Resistance /Anti Blood penetration |

ITEM | CSM100,CSM200,CSM300 |

Features & Benefits:

• Help to meet regulatory US and European standards AAMI LEVEL 1-4 EN13795

• With a barrier against liquids/bacterials/blood penetration

• Durable and good breathable laminates for increase comfort during surgical procedures

• Superior strength resists against tearing,low-lint of minimize particulates

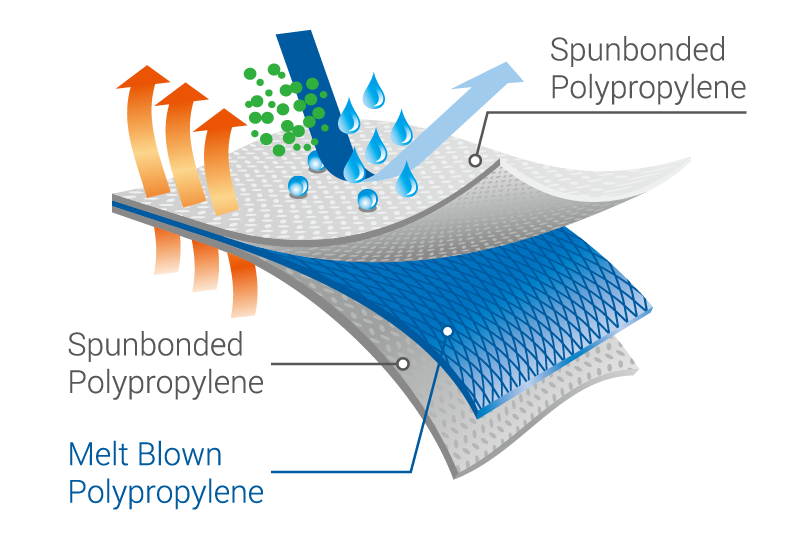

Spunbond Meltblown Spunbond, commonly known as SMS is a tri laminate non woven fabric. It is made up of a top layer of spunbond polypropylene, a middle layer of meltblown polypropylene and a bottom layer of spunbond polypropylene.

Spunbond is comparatively a faster way of producing polymer nonwovens as the technique results in faster belt speeds and manufactures low-cost products. The nonwoven materials manufactured using the meltdown technique have lower intrinsic strength than the spunbond.

Here are some of the many advantages of spunbond polypropylene Soft, durable, and breathable. Highly cost effective. Customizable to suit individual protective packaging needs. Lightweight and space saving compared to other protective packaging solutions.

Applications of Spunbond Nonwovens Various industries utilize the product for disposal purposes like masks, sanitary napkins, bandages, towels, wipes, child diapers, disposable dresses, carry bags, dust cloths, etc.

Spunlaid commonly known as Spunbond Nonwoven fabric are made up of the continuous process of fibres spun and directly dispersed into a web-like deflector or can be directed with air streams. This process leads to a faster belt speed.